Can You Make a Keyboard Out of Crayons? (Spoiler: No)

So, you want to make a mechanical keyboard out of crayons. It sounds colourful, creative... and really, really stupid. Let's break down exactly why this brilliant idea is doomed from the start, from melting points to structural integrity (or lack thereof).

What Are Crayons, Anyway?

Mostly Wax, Duh

A crayon is basically paraffin wax, which comes from petroleum oil. Its molecules form a crystal-like structure, which is what makes it solid and kinda hard. This structure is also why it's brittle - it chips and snaps easily.

But crayons aren't pure wax. Companies add their own secret ingredients, like stearic acid (a fatty acid that helps it stick together) to get the right feel for drawing. This means no two crayon brands are exactly alike, making them an unpredictable building material.

Weak and Melty

Let's be blunt, wax is a terrible material for building things. Its biggest feature is a low melting point, somewhere between 46°C and 68°C (115°F to 154°F). This also makes it a great insulator, which is a horrible quality for anything that holds electronics.

Mechanically, it's a wet noodle. It's soft, flows under pressure, and shatters with a small impact. Standard keyboard plastics like ABS and PBT are thousands of times stronger in every important way.

| Property | Crayon Wax | ABS (Normal Keycap Plastic) | PBT (Fancy Keycap Plastic) |

|---|---|---|---|

| Melting Point | 46−68∘C (115-154°F) | ≈200−250∘C (392-482°F) | ≈225∘C (437°F) |

| Tensile Strength | ≈1.2−1.4MPa (Very Weak) | ≈40−50MPa (Strong) | ≈50−60MPa (Stronger) |

| Thermal Conductivity | ≈0.2−0.3W/(m⋅K) (Insulator) | ≈0.17W/(m⋅K) (Insulator) | ≈0.22W/(m⋅K) (Insulator) |

| Shore D Hardness | Too soft to measure | ≈75−85 | ≈82 |

| Volumetric Shrinkage | 5−10% (A Lot!) | 0.4−0.8% (Very Little) | 1.5−2.5% (A Bit) |

That low melting point is a deal-breaker. Human skin temperature is around 33-37°C. This means your fingers are hot enough to melt the keycaps just by typing on them.

Wax that melts at body temperature is better known as petroleum jelly. You'd essentially be typing on sticky, greasy, color-stained Vaseline.

Brand Matters (Sort of)

So, which crayons are best for this bad idea? Premium brands like Crayola have more wax and less pigment, making them harder but more brittle. Cheaper knock-offs are softer, tackier, and weaker.

So you have a choice: a keyboard that shatters (premium) or one that melts and deforms (generic). Tough call.

Even worse, the color pigments are basically contaminants. They get in the way of the wax crystals, creating weak spots where cracks can start. The more colorful your crayon, the weaker it is. Great.

Mixing Colors Makes... Brown

If you think melting a rainbow of crayons will give you a beautiful swirl, think again. Color pigments work by absorbing light. When you mix them all together, they absorb almost all the light.

The result won't be a vibrant rainbow. It will be a dull, muddy brown or grey sludge. You'd have to pour each color separately, which is a whole other manufacturing nightmare.

Building the Case (and Watching It Fail)

Making the Mold

First, you need a mold. A flexible silicone mold is your best bet, since it's bendy enough to let you pop the fragile wax case out without breaking it. Using something rigid like plaster would be a disaster.

You'd build a box around an existing keyboard case, seal it up tight, and pour in the liquid silicone. Easy enough, but this is the last easy step.

Pouring the Wax

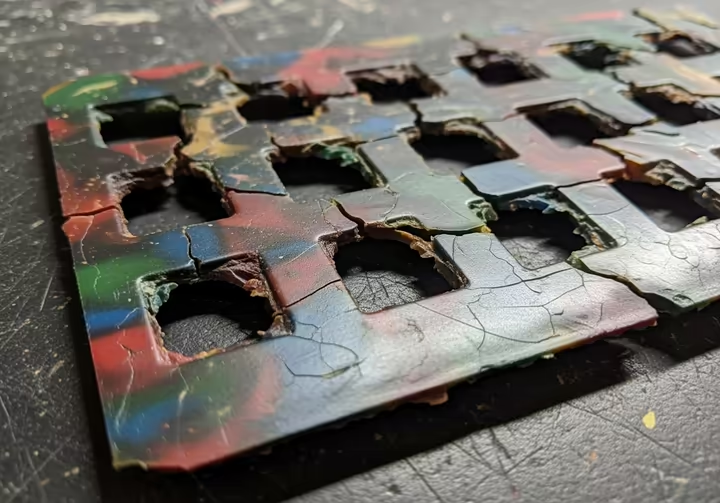

Now for the main event. You have to pour the wax slowly, at just the right temperature, to avoid defects. But there's a problem you can't solve: shrinkage.

Paraffin wax shrinks by 5-10% when it cools. This massive change in volume causes the real problems. You have to cool it slowly to prevent cracking, but because wax is an insulator, the outside hardens long before the inside.

As the molten core finally cools and shrinks, it pulls on the already-solid outer shell. This warps the case, creates giant sinkholes, and causes stress fractures. A flat keyboard case is practically impossible to make.

The Switch Plate Disaster

The switch plate, a 1.5mm sheet that holds the switches in place, is the most critical part. It needs to be precise and rigid. Wax is... neither.

A 1.5mm sheet of wax would be incredibly fragile, offering zero support. Switches would wobble, sit at weird angles, and pop out during use. The whole thing would be unusable.

And let's not forget soldering. To attach the switches to the circuit board, you need a soldering iron running at 350°C. Your case is made of wax. You see the problem? Any attempt at assembly would just melt the plate.

Making Keycaps Is Even Harder

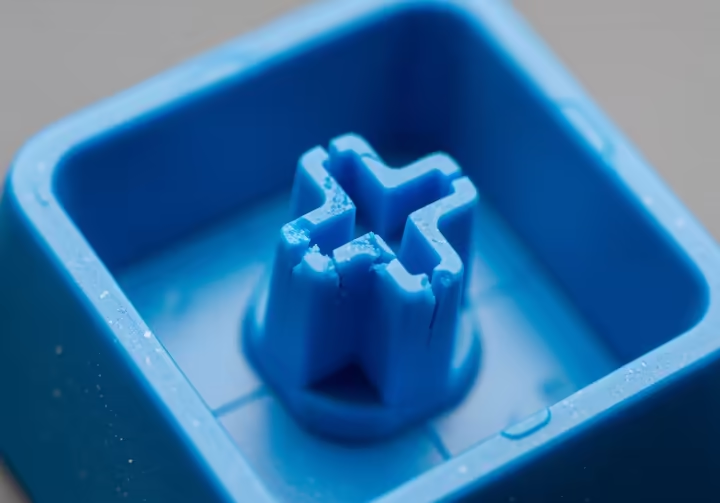

That Tiny Little Cross on the Bottom

The little cross-shaped mount on the bottom of a keycap has to be perfect, with tolerances of a few hundredths of a millimeter. Trying to mold this shape with a material that shrinks and warps as much as wax is hopeless.

The tiny features would probably snap off when you pull them from the mold. If they survived, they'd be so warped that the keycaps either wouldn't fit or would be incredibly loose.

Putting Letters on the Keys

How do you put letters on a wax keycap? You don't. Carving them would make the wax crumble. Molding them with a second color of wax would cause the first color to melt into an indistinct blob.

Lasers would just melt the surface, and ink wouldn't stick to the greasy wax. There is no good way to do this.

How It Feels to Use

The typing experience would be awful. The keycaps would feel waxy, greasy, and sticky as your body heat softens them, leaving colored residue on your fingers.

Your body heat and the friction from typing would literally smear the surface of the keycap. Any letters you managed to apply would be erased through normal use.

The keycaps would wear down in hours, and wobbly stems would transfer stress to the (already failing) wax switch plate, causing it to crack and fall apart.

The Inevitable Meltdown

Putting in the Electronics

There's no good way to install the electronics. You can't put the circuit board in before you pour the hot wax (it'll cook it). And you can't solder anything after, because the iron's heat will melt the case. You're stuck.

The Keyboard Cooks Itself

Since wax is a great insulator, it will trap all the heat generated by the keyboard's processor. Even though it's a low-power chip, the trapped heat will build up.

The internal temperature will rise until the wax around the electronics starts to soften, deform, and melt. This will let the circuit board shift around, causing wires to touch and creating a short circuit.

A Self-Destruct Sequence

It's basically a slow-motion thermal runaway. The chip generates heat, the wax case traps it, the wax melts, and the electronics short out.

That short circuit creates a big burst of heat, which rapidly melts more wax and could easily start a fire. The keyboard is designed to destroy itself.

How It Feels and Sounds

The Sound of Failure

Normal keyboards make a "thock" or "clack" sound from hard plastic parts hitting each other. A crayon keyboard is soft and absorbs sound. It wouldn't "thock" at all.

Instead, we need new words to describe the sound. Get ready for a "Viscous Impact" as the switch bottoms out in mush, a "Sebaceous Squish" as the greasy keycap rubs the housing, and a "Dull Amorphous Thud" from the lifeless case. You're hearing the sound of something slowly breaking.

It Feels Like Mush

The whole keyboard would bend when you press a key. The typing feel would be profoundly mushy and inconsistent. Keys in the middle would feel way softer than keys on the edges.

This mushiness would completely hide the subtle tactile bump from the switch itself. You wouldn't feel the switch working, you'd just feel the entire keyboard sagging under your finger like a wet sponge.

How Long Will It Last? (Not Long)

Don't Leave It in the Sun

The keyboard's lifespan would be measured in hours. A warm room will make it soft. Leaving it by a sunny window will turn it into a puddle. A hot mug of coffee placed nearby will leave a permanent crater.

Don't Drop It

Wax is brittle. If you drop it, it won't get a dent or a scratch. It will shatter into a million waxy pieces. Each keypress also causes a tiny, permanent amount of wear, meaning it has a predictable "Mean Keystrokes Before Failure"... which would be a very low number.

You Can't Clean It

Cleaning this thing is impossible. Water won't work (it's waterproof). A dry cloth will just smear the surface. Any solvent-based cleaner will literally dissolve it.

So, over time, it would just get covered in a permanent layer of dust, skin oils, and other grime. Gross.

Works cited

- Paraffin wax | Candle Making, Cosmetic Uses, Industrial Applications | Britannica, https://www.britannica.com/science/paraffin-wax

- Paraffin wax | 8002-74-2 - ChemicalBook, https://www.chemicalbook.com/ChemicalProductProperty_EN_CB2854418.htm

- Paraffin Wax Structure: Molecular Chains & Properties - Alphawax, https://alphawax.com/blog/paraffin-wax-structure

- Paraffin Wax - CALWAX, https://calwax.com/product/paraffin-waxes/

- Paraffin wax - Wikipedia, https://en.wikipedia.org/wiki/Paraffin_wax

- Crayons - Design Life-Cycle, http://www.designlife-cycle.com/crayons

- The Waxes Behind Your Favourite Drawing Sticks - SER spa, https://www.serwax.com/blog/drawing-wax

- Paraffin - WAX-EMULSIONS.COM, https://www.wax-emulsions.com/paraffin/

- Physical Properties and Main Classification of Paraffin - King Honor International Ltd., https://www.khonorwax.com/physical-properties-and-main-classification-of-paraffin.html

- Use of Paraffin Wax with Different Melting Points, https://www.khonorwax.com/use-of-paraffin-wax-with-different-melting-points.html

- characterization of paraffin wax, http://paraffinwaxco.com/paraffin-wax-characterization/

- Paraffin Wax PCM Heat Sinks | Electronics Cooling, https://www.electronics-cooling.com/wp-content/uploads/2023/08/Paraffin-Wax-PCM-Heat-Sinks.pdf

- US2127668A - High tensile strength wax - Google Patents, https://patents.google.com/patent/US2127668A/en

- EXPERIMENTAL STUDY OF PHYSICAL AND MECHANICAL PROPERTIES OF NATURAL AND SYNTHETIC WAXES USING UNIAXIAL COMPRESSIVE STRENGTH TEST - KFUPM, https://faculty.kfupm.edu.sa/PET/menamul/Artecal_publeshed/confurence_pup/Art%2012_Hossain%20et%20al%202009_ICMSAO_41-44246.pdf

- Paraffin wax compressive stress-strain curve | Download Scientific Diagram - ResearchGate, https://www.researchgate.net/figure/Paraffin-wax-compressive-stress-strain-curve_fig7_329248976

- Can I reduce melting temperature of paraffin? - ResearchGate, https://www.researchgate.net/post/Can-I-reduce-melting-temperature-of-paraffin

- Back to school : r/crappyoffbrands - Reddit, https://www.reddit.com/r/crappyoffbrands/comments/91e7n7/back_to_school/

- Compared: Crayola Crayons vs. Generic - YouTube, https://www.youtube.com/watch?v=8yxqEin-7CM

- FAQ | How are Crayola crayons made?, https://www.crayola.ca/faqs/how-are-crayons-manufactured-and-what-are-the-basic-ingredients

- Subtractive Color Mixing: Principles & Practical Applications - EPACK, https://www.epackprinting.com/cmyk-subtractive-color-mixing/

- Subtractive color - Wikipedia, https://en.wikipedia.org/wiki/Subtractive_color

- www.ccs-grp.com, https://www.ccs-grp.com/guide/theory-light-color/15_color-mixing-1-additive-subtractive.html#:~:text=Principle%20of%20Subtractive%20Color%20Mixing&text=Equal%20mixing%20of%20yellow%20(Y,amounts%20produces%20black%20(K).

- Additive vs Subtractive Color: A Complete Guide - Arounda, https://arounda.agency/blog/additive-vs-subtractive-color-a-complete-guide

- How to Make Silicone Molds: A Practical Guide - Formlabs, https://formlabs.com/blog/how-to-make-silicone-molds/

- Tutorial: How to Make a Silicone Rubber Candle Mold - Polytek Development Corp., https://polytek.com/tutorial/tutorial-how-to-make-a-silicone-rubber-candle-mold/

- How to Make a Mold for Lost Wax Casting - Instructables, https://www.instructables.com/How-to-make-a-mold-for-lost-wax-casting/

- Can i just use plaster of paris for lost wax casting : r/MetalCasting - Reddit, https://www.reddit.com/r/MetalCasting/comments/ea43dq/can_i_just_use_plaster_of_paris_for_lost_wax/

- How to Solve Wax Shrinkage and Cracking in Detailed Candle Molds, https://candlesmolds.com/blogs/news/how-to-solve-wax-shrinkage-and-cracking-in-detailed-candle-molds

- How To Prevent From Candle Shrinkage? Causes & Fixes - VedaOils, https://www.vedaoils.com/blogs/candlemaking/why-does-candle-wax-shrink

- Paraffin Wax, https://southwestwax.com/product/paraffin-waxes/

- Influence of temperature conditions on the shrinkage of wax patterns for investment casting, https://www.researchgate.net/publication/344665728_Influence_of_temperature_conditions_on_the_shrinkage_of_wax_patterns_for_investment_casting

- wax shrinkage | Silicone rubber mould | Pattern wax | Investment casting, http://paraffinwaxco.com/wax-shrinkage/

- How much space goes between a PCB and a plate on a standard mechanical board? : r/MechanicalKeyboards - Reddit, https://www.reddit.com/r/MechanicalKeyboards/comments/bhv2c8/how_much_space_goes_between_a_pcb_and_a_plate_on/

- Custom keyboard plate design & manufacturing - GOLEM, https://golem.hu/guide/keyboard-plate-manufacturing/

- How thick should be switch plate for MX switches? : r/ErgoMechKeyboards - Reddit, https://www.reddit.com/r/ErgoMechKeyboards/comments/1c7rfgw/how_thick_should_be_switch_plate_for_mx_switches/

- Step-by-Step Guide to Choosing Your Ideal Keyboard Plate Material - KNC Keys LLC, https://knckeys.com/blogs/blogs/step-by-step-guide-to-choosing-your-ideal-keyboard-plate-material

- Plate Material, Does It Make a Difference? - LumeKeebs, https://lumekeebs.com/blogs/blog/plate-materials-does-it-make-a-difference

- Mechanical Keyboard Plates: How to Choose the Right Material for Your Next Build - HHKB, https://hhkeyboard.us/blog/mechanical-keyboard-plate

- Plate Materials & Sizes - Keyboard University, https://www.keyboard.university/200-courses/plate-materials-sizes-9yn46

- www.aixuntech.com, https://www.aixuntech.com/newsinfo/what-is-the-best-temperature-for-a-soldering-station/

- What's the proper soldering iron temperature for standard .031" 60/40 solder?, https://electronics.stackexchange.com/questions/1980/what-s-the-proper-soldering-iron-temperature-for-standard-031-60-40-solder

- Cherry MX mount. - Deskthority, https://deskthority.net/viewtopic.php?t=11183

- Custom Cherry MX plate measurements. - Deskthority, https://deskthority.net/viewtopic.php?t=20144

- Cherry common part number schema - Telcontar.net, https://telcontar.net/KBK/Cherry/common_schema

- gimsuncustom.com, https://gimsuncustom.com/blogs/gimsuncustom-keyboard-keycaps/a-closer-look-at-legends-and-sub-legends#:~:text=Different%20Methods%20of%20Creating%20Legends%20and%20Sub%2DLegends&text=Laser%2Detched%3A%20In%20laser%2D,depending%20on%20the%20filling%20material.

- Mechanical Keycaps Production Process and Materials - KreativeKeys, https://kreativekeys.gg/blogs/all-things-kreativekeys/how-the-keycap-is-made

- What are doubleshot keycaps? Are they really worth it? - Glorious, https://www.gloriousgaming.com/blogs/resources/what-are-double-shot-keycaps

- Fading Legends? Here's the Truth About Keycap Printing Methods - Awekeys, https://awekeys.com/blogs/news/fading-legends-here-s-the-truth-about-keycap-printing-methods

- The function and use of paraffin wax, https://www.fengcheng-sm.com/new_show.asp?nid=1800

- Wax Additives - Deuteron GmbH, https://deuteron.com/wp-content/uploads/pdf/flyer-waxes-E.pdf

- Paraffin MSDS, https://www.uww.edu/apps/riskmanagement/msds/paraffin_sciencelab_10.10.05.pdf

- Paraffin Wax Flash Points - Shamrock Candles, http://www.shamrockaffiliations.ws/candle-making-tips/paraffin-wax-flash-points.html

- Broken microcontroller: what to do next - Deskthority, https://deskthority.net/viewtopic.php?t=21038

- Microcontroller overheating? : r/MechanicalKeyboards - Reddit, https://www.reddit.com/r/MechanicalKeyboards/comments/3ffd7n/microcontroller_overheating/

- Prevent Fire Hazards From Short Circuits - A to Z Electric Co., https://www.electricatoz.com/prevent-fire-hazards-from-short-circuits/

- What is a Short Circuit and Why is it Dangerous? - Add-All Electric, https://addallelectric.com/e-tips/what-is-a-short-circuit-and-why-is-it-dangerous/

- Understanding How Electrical Short Circuits Can Cause Fires, https://vivoasia.com/how-electrical-shorts-cause-fires/

- Understanding Thermal Runaway in Lithium-Ion Batteries - EcoFlow US Blog, https://www.ecoflow.com/us/blog/understanding-thermal-runaway-in-lithium-ion-batteries

- Understanding Thermal Runaway – and Solutions for Designing Safer Batteries - Tapecon, https://www.tapecon.com/blog/understanding-thermal-runaway-and-solutions-for-designing-safer-batteries

- Thermal runaway - Wikipedia, https://en.wikipedia.org/wiki/Thermal_runaway

- Creamy, Clacky, Thocky – Which Sound Profile Do You Prefer for Your Ke - Awekeys, https://awekeys.com/blogs/news/creamy-clacky-thocky-which-sound-profile-do-you-prefer-for-your-keyboard-choosing-the-right-switches-from-awekeys

- clack and thock the only sound profiles available - what else is there : r/MechanicalKeyboards - Reddit, https://www.reddit.com/r/MechanicalKeyboards/comments/1lsqrty/clack_and_thock_the_only_sound_profiles_available/

- What the thock is clack? - A Discussion on Switch Sound, https://www.theremingoat.com/blog/what-the-thock-is-clack-a-discussion-on-switch-sound

- "Thocc" vs "Clack" (My tips from a beginner for other beginners) : r/MechanicalKeyboards, https://www.reddit.com/r/MechanicalKeyboards/comments/16witz0/thocc_vs_clack_my_tips_from_a_beginner_for_other/

- Cases, Plates & Mods – How Materials Change Sound | Click and Thock, https://www.clickandthock.com/other-sound-tests

- How does plate material effect feel in a tray mount keyboard? - KeebTalk, https://www.keebtalk.com/t/how-does-plate-material-effect-feel-in-a-tray-mount-keyboard/8638

- Keyboard Mounting Styles, https://www.keyboard.university/200-courses/keyboard-mounting-styles-4lpp7

- What is Haptic Feedback and How Does it Works? - Hallmark Nameplate, https://www.hallmarknameplate.com/tactile-feedback-works/

- (PDF) Haptic Feedback Intensity Affects Touch Typing Performance on a Flat Keyboard, https://www.researchgate.net/publication/270905522_Haptic_Feedback_Intensity_Affects_Touch_Typing_Performance_on_a_Flat_Keyboard

- Cherry Mechanical Switch Guide - Keychron Germany, https://keychron.de/blogs/news/cherry-mechanical-switch-guide

- Paraffin Wax Candle FAQ - Koch & Co, https://www.koch.com.au/paraffin-wax-candle-faq

- Safety Data Sheet Paraffin Wax Revision 5, Date 01 Jan 2022 - Redox, https://redox.com/wp-content/sds/1319.pdf

- Performance effect of applying paraffin wax on solar photovoltaic backplate - ResearchGate, https://www.researchgate.net/publication/331148169_Performance_effect_of_applying_paraffin_wax_on_solar_photovoltaic_backplate

- Wax usage - expiration/storage - Candle Making Supplies, https://generalwaxcandlemaking.com/blogs/news/wax-usage-expiration-storage

- UV Inhibitor - The Flaming Candle, https://www.theflamingcandle.com/accessories-additives/additives/uv-inhibitor/

- Simple Guide to UV Inhibitors - Armatage Candle Company, https://armatagecandlecompany.com/blog/uv-inhibitors/

- WAXES: PARAFFIN - CAMEO Chemicals - NOAA, https://cameochemicals.noaa.gov/chemical/18025