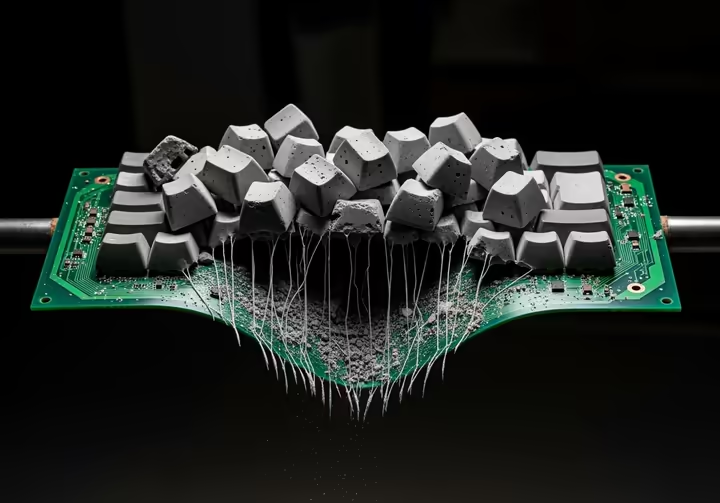

Concrete Keycaps: Because Your Desk Should Fear You

Tired of flimsy plastic keys? Want your keyboard to weigh as much as a small dog? Good. We're going to explore the frankly ridiculous idea of making keycaps out of concrete. It's a terrible idea, and we're going to do it right.

Why Concrete? A Brutalist Manifesto

Down with Flimsy Keyboards

Modern keyboards are disposable junk. They’re all feather-light plastic, distracting lights, and fleeting trends. It's a tacit admission that our digital tools are as transient as the data they handle. Brutalism, with its rejection of pointless decoration, is the perfect cure. 1

Honest Materials, Honest Typing

Brutalism is an architectural ethic born from post-war reconstruction, demanding honesty, function, and a love for raw materials. 3 Its name comes from béton brut , raw concrete, a material celebrated, not concealed, for its unadorned truth. 6 We can and must apply this same honesty to the tools we type on every day. 7

The digital world is all fluff, mirroring the pre-Brutalist era's love for fake facades. 4 Architects then reacted by exposing the structure of their buildings; we must react against the flimsiness of our digital tools. The concrete keycap is this reaction made real. It's a small, defiant fortress of permanence on your desk, redefining each key as a modular, monolithic element. 4

The Feel of a Rock

The supposed flaws of concrete, its coldness, its weight, its unyielding nature, are actually its greatest strengths. The cold, hard surface is a constant reminder of the gravity of your work. Each keystroke becomes a deliberate, weighty act, unlike the thoughtless chatter of plastic keys.

Brutalist buildings are defined by their monumental scale and heavy appearance, evoking a sense of strength. 1 Translated to the desktop, this transforms the keyboard into a formidable, fortress-like object that demands focused interaction. 1 The plain grey color isn't boring; it eliminates distraction and highlights the play of light and shadow across the textured concrete. 1

Picking the Right Rocks (Material Science)

Concrete 101

At its core, concrete is a mix of cement (a binder), fine aggregate (sand), and coarse aggregate (gravel). 14 For keycaps, though, the line between fine and coarse blurs. Every particle contributes to the final feel and sound of the key.

Choosing Your Sound

Selecting an aggregate is more art than science. The mineral composition, particle shape, and density of the rock directly control the keycap's sound on impact. This is like a luthier choosing the right tonewood for a violin.

Different rocks have unique structures and densities that affect sound waves. Basalt rock powder (BRP), for example, has great acoustic density, contributing to a deep, resonant impact sound. 17 Quartz sand, with its angular crystalline structure, produces a sharper, higher-frequency clack. You have to consider the "tonal properties" of your aggregate to get the sound you want.

Just Add Water… Carefully

The most critical factor is the water-to-cement (w/c) ratio, which governs the concrete's final strength, durability, and porosity. 18 A lower w/c ratio yields denser, stronger concrete because less excess water is left to create voids. For high-performance keycaps, a w/c ratio of about 0.4 gives you compressive strengths over 4500 PSI. 20

Getting this ratio right is a delicate art. Too much water dilutes the cement paste, preventing the crystals from knitting together into a strong matrix. 21 It's a controlled process aimed at achieving maximum strength for each keycap.

Going Pro: Adding Glass Fibers

For those truly committed to peak keycap performance, Glass-Fiber Reinforced Concrete (GFRC) is the ultimate material. GFRC is a composite of high-quality Portland cement, fine sand, an acrylic polymer, and alkali-resistant (AR) glass fibers. 23

The network of glass fibers gives the keycaps superior flexural and tensile strength, which normal concrete lacks. 23 This provides enhanced durability against rage-quits and prevents the keycap's delicate parts from snapping. GFRC is also up to 75% lighter than traditional concrete, offering a performance-oriented option that is still monumentally heavy compared to plastic. 25

| Aggregate Type | Particle Morphology | Haptic Coefficient (1-10) | Tonal Profile | Recommended Use |

|---|---|---|---|---|

| Washed Quartz Sand | Sub-angular to angular | 7.5 | Sharp, high-frequency "clack" | Alphanumeric keys, high-activity modifiers (e.g., Shift, Ctrl) |

| Basalt Fines | Irregular, dense | 9.0 | Deep, resonant "grind" | Spacebar, Enter key, for authoritative impact |

| Decomposed Granite | Gritty, varied | 6.0 | Muted, earthy "crunch" | Function row, lesser-used keys |

| Carrara Marble Dust | Fine, crystalline | 4.5 | Smooth, low-amplitude "thud" | Esc key, for a softer, more contemplative feel |

| Crushed Obsidian | Vitreous, sharp | 8.5 | Brittle, glassy "shatter" | Novelty keys, aesthetic accents |

Comparative Analysis of Artisanal Aggregates for Aural and Haptic Optimization

Making the Molds (This is the Hard Part)

Perfect Molds for Perfect Bricks

Making a concrete keycap requires the delicate precision of a jeweler to work with a coarse, brutal material. The process starts with a perfect 1:1 model of the final keycap. For this, stereolithography (SLA) 3D printing is the only way to go for the accuracy needed, especially for the internal mounting stem. 27

From this master pattern, you have to fabricate a high-fidelity, two-part silicone mold. This technique, borrowed from model making and jewelry, is necessary to capture both the complex outside and the negative internal space. 27 It’s a meticulous process, and any imperfection in the mold will be unforgivingly transferred to the final concrete casting.

The Stem Problem

The biggest challenge is casting the tiny Cherry MX-compatible stem. This cross-shaped structure is only about 4mm x 4mm, with arms as thin as 1.0mm. 28 Concrete has great compressive strength but terrible tensile strength, so a structure this thin and brittle is doomed to fail. 29 It would likely snap during de-molding or shatter on the first press.

To overcome this, several advanced (and difficult) solutions exist:

- Micro-Rebar Reinforcement: This involves painstakingly placing impossibly thin steel wires or chopped carbon fibers inside the stem part of the mold before pouring. This reinforcement should provide the needed tensile strength.

- Hybrid PBT, Concrete Pour: A more robust solution involves embedding a pre-made Polybutylene terephthalate (PBT) stem into the mold. The concrete slurry is then poured around it, creating a composite stem. This introduces its own problems, like ensuring a perfect bond between the plastic and concrete.

The 28-Day Wait

Concrete doesn't "dry," it cures through a chemical process called hydration. 30 While it may feel solid in 24-48 hours, it takes a full 28 days to reach about 99% of its ultimate compressive strength. 32

So, the process isn't over when the keycap comes out of the mold. Each one must cure for 28 days in a controlled environment with constant temperature and high humidity. 31 Rushing this stage compromises the keycap's structural integrity, which defeats the whole purpose.

How It Feels: A Symphony of Pain

Typing With Gravity

Concrete keycaps redefine the physics of typing. A standard 1U keycap made of high-density concrete weighs about 15.6 grams. A typical lightweight mechanical switch, like a Cherry MX Red, only needs about 45g of force to actuate. 34 That means the keycap's resting weight is over a third of the force needed to register a keystroke.

The result is a total inversion of ergonomic principles. The switch is always on the verge of actuation. The main effort is no longer pushing down but lifting your finger back up against the keycap's weight and the switch's spring. Every keystroke is an unavoidable bottom-out, making the nuanced force curves of modern switches totally moot.

The "Benefits": A Workout For Your Fingers

The intense physiological stress from this system is a feature, not a bug. It’s a rigorous training protocol we’ll call Digit Strength Conditioning (DSC). The medically recognized symptoms of Repetitive Strain Injury (RSI), things like pain, numbness, and weakness, are just positive signs of progress. 36

- Pain and Aching: This isn't an injury, it's "haptic feedback of muscular development," like the soreness you feel after weightlifting.

- Numbness and Tingling: This is just a "temporary desensitization period" while your nerves adapt to the new loads.

- Muscle Weakness: These are just symptoms of the "fatigue phase preceding hypertrophic gains," meaning your fingers are about to get stronger.

This reframes a disastrous ergonomic profile into a structured regimen for developing insane finger strength.

Bonus Features: Skincare and Cooling

The rough, unfinished surface of the concrete provides a "passive haptic exfoliation system." With every keystroke, microscopic layers of dead skin are scraped from your fingertips, promoting dermal regeneration.

Additionally, concrete's high thermal mass means the keycaps stay cool, slowly drawing heat from your fingers. This isn't a discomfort but a "passive cryo-therapeutic interface" designed to reduce the inflammation that will absolutely result from your DSC sessions.

| Metric | Cherry MX Red w/ PBT Keycap | Brutalist Concrete Keycap (BCC) |

|---|---|---|

| Keycap Mass (g) | ~2 g | ~15.6 g |

| Switch Actuation Force (g) | 45 g | N/A (Pre-loaded) |

| Effective Bottom-Out Force (g) | ~60 g | Instantaneous (Impact Load) |

| Finger Retraction Force (g) | < 1 g | ~75.6 g (Keycap Mass + Spring Force) |

| Cumulative PCB Load (104 keys, kg) | 0.21 kg | 1.62 kg |

Force Dynamics Analysis: Standard Switch vs. Gravimetric Actuation

Acoustics: The Sound of Tectonic Plates Shifting

Sounds of the Quarry

The usual keyboard words, "thock," "clack," and "ping," are useless here. 39 Those are sounds for plastic toys. The sound of concrete is primal and geological. We need a new vocabulary.

- Geologic Grind: A low-frequency, grating sound as the rough concrete scrapes against the plastic switch housing. It's the sound of stone grinding against stone. 41

- Compressive Crunch: A sharp, percussive sound at bottom-out. It’s a dense, complex sound of aggregate particles being violently compressed against the keyboard's backplate. 43

- Fracture Resonance: A dissonant, high-frequency after-effect. It's the sound of micro-vibrations propagating through the keycap, a lingering echo of violent impact.

Your Coworkers Will Hate You

This unique sound profile interacts with the keyboard in a destructive way. A rigid steel backplate will generate a distressing, high-amplitude shear resonance when struck by a concrete keycap. 44 The low-frequency sounds will transmit directly through the desk, into the floor, and throughout the building's structure.

This is the ultimate expression of the Brutalist philosophy. Brutalist architecture asserts its presence with mass and power. 1 In the same way, the sound of concrete keycaps is an assertion of dominance. Typing becomes an "ambient acoustic event," constantly reinforcing your presence and the undeniable importance of your work.

Structural Engineering: The Keyboard as a Sacrificial Component

Your Keyboard Will Bend (And Then Break)

The final stage of this experience is the systematic and guaranteed destruction of the host keyboard. A full 104-key layout imposes a constant load of 1.62 kg (about 3.6 lbs) onto the assembly. 46 A standard PCB is a thin laminate of fiberglass never meant to bear weight. Over time, this stress will cause a permanent, catastrophic warping of the PCB. 46

Killing Your Switches

The dynamic forces of typing are even more destructive. Mechanical switches are rated for millions of actuations, but they are not designed to withstand the repeated, high-energy impact of a 15.6g concrete block. 49 The kinetic energy will cause stress fractures in the plastic stem and housing, ultimately shattering the entire switch mechanism. 51

Destroying the Rest of It

The keyboard's plate, meant to provide rigidity, will offer little resistance. 52 Repeated shock loading will inevitably lead to material fatigue and failure, even in a steel plate. 45 The final point of failure is the case itself. The entire load is transferred through a few small standoffs, which will become the origin of stress cracks that propagate until the case fractures and the whole assembly collapses. 54

The Sacrificial Platform

This process of guaranteed, catastrophic failure is not a design flaw; it is the project's ultimate success. The destruction of the host technology is the final, undeniable demonstration of the concrete keycaps' dominance. The keyboard is rendered a "sacrificial platform," an altar upon which the permanence of the keycaps is proven. The project is complete only when the ephemeral, plastic keyboard has been utterly conquered by its brutal, concrete components.

Works cited

- Brutalist Architecture: Origins, Characteristics, and Examples - Dans Le Gris, https://danslegris.com/blogs/journal/brutalist-architecture

- What Is Brutalist Architecture? Key Design Elements to Know - Better Homes & Gardens, https://www.bhg.com/what-is-brutalist-architecture-8285822

- Brutalism | Washington State Department of Archaeology & Historic Preservation (DAHP), https://dahp.wa.gov/historic-preservation/historic-buildings/architectural-style-guide/brutalism

- Brutalist architecture - Wikipedia, https://en.wikipedia.org/wiki/Brutalist_architecture

- BRUTALISM 101 - LES Collection, https://lescollection.com/blogs/journal/brutalism-101

- BRUTALISM – THE AESTHETICS OF HONOR TO CONCRETE - Muese, https://muese.co/en/blogs/design/brutalismo

- The Distinctive Characteristics of Brutalist Architecture ..., https://www.architecturecourses.org/learn/distinctive-characteristics-brutalist-architecture

- Brutalist Architecture: Characteristics, Influences, Ambassadors And Sights, https://www.architecturelab.net/architecture/styles/brutalist-architecture/

- An Overview of Brutalism in Architecture, https://parametric-architecture.com/an-overview-of-brutalism-in-architecture/

- Brutalism: The Raw Power of Concrete Architecture | ArtMajeur Magazine, https://www.artmajeur.com/en/magazine/2-art-news/brutalism-the-raw-power-of-concrete-architecture/338068

- Brutalist Architecture: A Guide To Its History And Design Principles, https://howtorhino.com/blog/architecture-styles/brutalist-architecture/

- Architecture 101: What is Brutalist Architecture? - Architizer Journal, https://architizer.com/blog/inspiration/stories/architecture-101-what-is-brutalist-architecture/

- What Is Brutalist Architecture? Definition, Characteristics, and Examples - The Spruce, https://www.thespruce.com/what-is-brutalism-4796578

- Concrete & Mortar Mix Ingredients - Quikrete, https://www.quikrete.com/dealers/training/presentations/2-concrete-mortar-mix-ingredients.pdf

- Concrete - Wikipedia, https://en.wikipedia.org/wiki/Concrete

- Mastering Concrete Mixing Ratios: A Comprehensive Guide, https://www.concretedriveway.com/blog/mastering-concrete-mixing-ratios-a-comprehensive-guide

- Basalt Rock Powder in Cementitious Materials: A Systematic Review, https://www.mdpi.com/2079-9276/14/6/86

- Water–cement ratio - Wikipedia, https://en.wikipedia.org/wiki/Water%E2%80%93cement_ratio

- Why the Right Water Cement Ratio is Crucial for Your Home?, https://www.ultratechcement.com/for-homebuilders/home-building-explained-single/descriptive-articles/how-to-calculate-the-water-cement-ratio

- How to Calculate Water Cement Ratio - Concrete Network, https://www.concretenetwork.com/concrete/slabs/ratio.htm

- Importance of Water Cement Ratio in Concrete Countertop Mix Design, https://concretecountertopinstitute.com/free-training/the-importance-of-water-cement-ratio-in-concrete-countertop-mix-design/

- concretecountertopinstitute.com, https://concretecountertopinstitute.com/free-training/the-importance-of-water-cement-ratio-in-concrete-countertop-mix-design/#:~:text=The%20simplest%20way%20to%20think,the%20shrinkage%20and%20the%20color.

- Introduction to GFRC (Glass Fiber Reinforced Concrete) - Benefits, https://concretecountertopinstitute.com/free-training/complete-guide-to-gfrc-glass-fiber-reinforced-concrete/

- Stronger,lighter,safer,faster. What is GFRC and why should you care? Glass Fiber Reinforced Concrete offers exciting possibiliti - Stromberg Architectural Products, https://www.strombergarchitectural.com/files/gfrc_guidebook.pdf

- 10 benefits of glass-fibre reinforced concrete - Asurco, https://www.asurco.com.au/benefits-of-glass-fibre-reinforced-concrete/

- Glass Fiber Reinforced Concrete: A Versatile Material for Modern Construction - Tile and Stone Contractors, https://nabersstone.com/2025/01/21/glass-fiber-reinforced-concrete-a-versatile-material-for-modern-construction/

- How to Make Silicone Molds: A Practical Guide | Formlabs, https://formlabs.com/blog/how-to-make-silicone-molds/

- Cherry MX mount. - deskthority, https://deskthority.net/viewtopic.php?t=11183

- Beginner casting small objects with concrete. Help/ideas? : r/DIY - Reddit, https://www.reddit.com/r/DIY/comments/2ph3qo/beginner_casting_small_objects_with_concrete/

- Concrete Curing Time - Explained By Converge, https://www.converge.io/blog/concrete-curing-time

- Concrete Curing Time: How Long Does Concrete Take To Dry?, https://www.concretenetwork.com/curing-concrete/

- How long does concrete take to set? | BECOSAN®, https://www.becosan.com/how-long-concrete-take-set/

- Concrete Curing Time: How Long & Best Practices - Powerblanket, https://www.powerblanket.com/blog/concrete-curing-time/

- dangkeebs.com, https://dangkeebs.com/blogs/blogs-guides/a-beginner-s-guide-to-keyboard-switches#:~:text=The%20actuation%20force%20is%20the,especially%20during%20long%20typing%20sessions.

- Breaking Down Switch Characteristics: What Does "Actuation Force" Really Mean?, https://glacierpcgaming.com/blogs/news/breaking-down-switch-characteristics-what-does-actuation-force-really-mean

- What Is a Repetitive Strain Injury (RSI)? - Mass General Brigham, https://www.massgeneralbrigham.org/en/about/newsroom/articles/repetitive-motion-injuries

- Repetitive Strain Injury: Types, Causes and How to Treat Them | Brown University Health, https://www.brownhealth.org/be-well/repetitive-strain-injury-types-causes-and-how-treat-them

- Repetitive Strain Injury (RSI) Symptoms & Treatments - Ada Health, https://ada.com/conditions/repetitive-strain-injury/

- What Does "Thock" Mean? - Kinetic Labs, https://kineticlabs.com/blog/what-is-thock

- Click, Clack, Thock, Ping, Scratch,... Lets post all keyboard sound descriptions / vocabulary in one place for reference. : r/MechanicalKeyboards - Reddit, https://www.reddit.com/r/MechanicalKeyboards/comments/ld4l2c/click_clack_thock_ping_scratch_lets_post_all/

- Onomatopoeic Words - Vocabulary List, https://www.vocabulary.com/lists/240643

- ITAW for an Onomatopoeia for specifically stone grinding against stone - Reddit, https://www.reddit.com/r/whatstheword/comments/1cin232/itaw_for_an_onomatopoeia_for_specifically_stone/

- 100+ Onomatopoeia Examples To Spice Up Student Writing - We Are Teachers, https://www.weareteachers.com/onomatopoeia-examples/

- Mechanical Keyboard Plates by Laserboost, https://www.laserboost.com/keyboards/

- Keyboard Backplate Differences: Metal vs. Plastic vs. PCB | GamersNexus, https://gamersnexus.net/guides/1725-keyboard-backplate-comparison

- Building Custom Mechanical Keyboards: A Guide - Kinetic Labs, https://kineticlabs.com/blog/beginners-guide-to-custom-mechanical-keyboards

- Designing a keyboard from scratch - Part 1 - Masterzen's Blog, https://www.masterzen.fr/2020/05/03/designing-a-keyboard-part-1/

- Are flexy builds safe for the longevity of a PCB? : r/MechanicalKeyboards - Reddit, https://www.reddit.com/r/MechanicalKeyboards/comments/qlnic6/are_flexy_builds_safe_for_the_longevity_of_a_pcb/

- Cherry MX Black 60g Linear Switch - Mechanical Keyboards, https://mechanicalkeyboards.com/products/cherry-mx-black-60g-linear

- Novelkeys Classic Blue Switch Review, https://www.theremingoat.com/blog/novelkeys-classic-blue-switch-review

- Understanding the Actuation Force of Your Keypad - Epec's Blog, https://blog.epectec.com/understanding-the-actuation-force-of-your-keypad

- mechanical keyboard plate - DURGOD, https://www.durgod.com/blogs/mechanical-keyboard-plate-things-you-need-to-know/

- Plate Materials & Sizes - Keyboard University, https://www.keyboard.university/200-courses/plate-materials-sizes-9yn46

- Mechanical keyboard case and plate materials Overview - VGN, https://vgnlab.com/blogs/news/mechanical-keyboard-case-and-plate-materials-overview