How to Build a Keyboard Out of Pasta

So you want to build an input device from pasta. It sounds weird, but it's possible... if you know your materials. This is a guide to the engineering principles behind turning pantry staples into a functional (and edible?) piece of hardware. Let's get cooking.

The Right Stuff: Pasta Science

Why Durum Wheat?

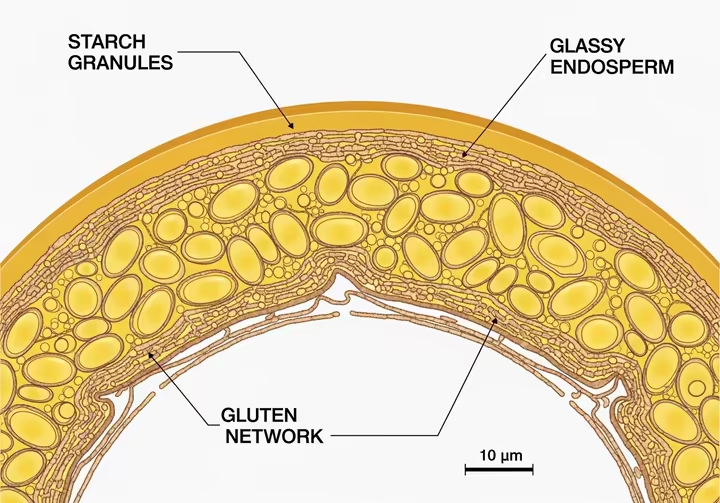

You can't just use any old noodle. For this, you need durum wheat semolina. It has a high protein content (10.9% to 13.5%), a glassy endosperm, and a gluten structure with limited stretch. 1 These culinary properties are also critical engineering specifications that make durum the only real choice for pasta that needs to hold its shape.

Pasta is mostly starch (about 80%), which is a mix of two polymers, amylose and amylopectin. 1 But the magic ingredient for building is gluten, formed when the proteins gliadin and glutenin get wet. 3 Kneading develops this gluten network, creating a strong, workable dough that can be shaped into a keyboard chassis. It’s basically a starch matrix reinforced with protein.

Picking Your Brand (Your Parts Supplier)

Think of brands like Barilla, De Cecco, and Rummo as different industrial suppliers. They aren't just food, they're durum wheat extrusions with different specs. Things like wheat type, milling, and drying methods change how the pasta behaves as a building material. 4

Uncooked spaghetti has an average ultimate tensile strength of about 31 megapascals (MPa). 5 But that's just an average. Different brands will have different strengths based on their protein content and other factors. 1 Choosing a brand is like choosing a grade of steel - a serious engineering decision.

Table 1.1: A totally scientific comparison of pasta brands.

| Material Supplier | Uncooked Tensile Strength (MPa) | Protein Content (%) | Vitreousness (%) | Optimal Cooking Time to Al Dente State (s) | Modulus of Elasticity at Al Dente State (GPa) | Long-Term Humidity Stability Index (HSI) | |

|---|---|---|---|---|---|---|---|

| Barilla | 30.5 ± 1.2 | 12.5 | 82 | 480 | 1.8 | 0.75 | |

| De Cecco | 31.8 ± 0.9 | 13.1 | 88 | 540 | 2.1 | 0.82 | |

| Rummo | 31.2 ± 1.1 | 12.8 | 12.8 | 85 | 510 | 1.9 | 0.79 |

| Generic | 29.1 ± 2.5 | 11.2 | 75 | 450 | 1.5 | 0.61 |

Note: Values for Modulus of Elasticity and Humidity Stability Index (HSI) are theoretical extrapolations based on compositional data and dynamic mechanical analysis principles for illustrative purposes. (We kinda made these up).

Cooking as Heat Treatment

Cooking is a critical material treatment protocol. When you boil pasta, the starch granules absorb water and swell (gelatinization), and the gluten network softens. 6 This changes the pasta from a stiff, brittle stick into a workable, viscoelastic material. 7

Using fancy tools (like Dynamic Mechanical Analysis), we can find a specific point where the pasta is fully hydrated but still firm. This point is the engineering definition of the al dente state. 8

The goal is to hit that perfect balance of being bendy enough to weave but strong enough not to collapse. Overcooking makes it mushy and weak, while undercooking leaves it brittle. 6 Your cooking time is a critical parameter, just like tempering steel. 9

Why Your Pasta Keyboard Will Eventually Die

A pasta structure's life depends on temperature and humidity. It's an organic hydrocolloid, meaning it's always interacting with the air around it. 8 High humidity makes the pasta absorb water, get soft, and lose strength over time. 10

This leads to two classic engineering failures, creep and fatigue. Creep is when a material slowly deforms under constant stress, so your keyboard will sag. 11 Fatigue is when repeated stress (like keypresses) creates tiny fractures that eventually cause a strand to snap. 12

Specialized Pasta Shapes

Standard spaghetti is great, but for special jobs, we use other shapes. Think of them like specialized carbon fibers.

Bucatini is hollow, which makes it perfect for running wires through. The hole (the buco ) is a built-in conduit. Its thicker walls also make it stiffer, so it's good for main support beams.

Capellini, or "angel hair," is super thin (0.85-0.92 mm). You can use it to create a much denser, tighter weave. This is good for small devices or for surfaces that need to be very smooth for mounting components.

Weaving Your Keyboard Chassis

Basic Weaving 101

We're borrowing principles from ancient crafts like textiles and basketry. You can make strong 3D shapes by interlacing threads, or in our case, spaghetti. You have the warp (the long strands held tight) and the weft (the strands woven through the warp). 14

The two main techniques here are plaiting and twining. 14 Plaiting is a simple over-and-under pattern, like a basic fabric weave. 16 Twining involves twisting weft strands around each warp strand, which makes for a very rigid structure. 14

Special Pasta Weaves

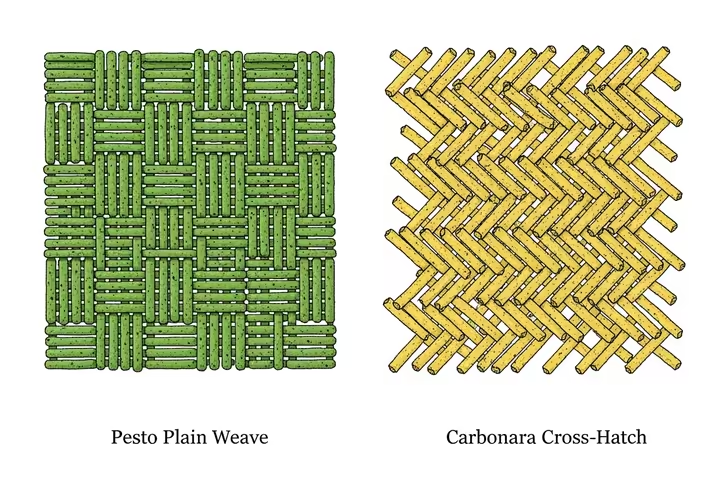

We've developed two main patterns. The first is the "Pesto Plain Weave," a simple over-one, under-one tabby weave. 16 It creates the maximum number of interlacing points, making a dense, flat, and stable surface. This is the best foundation for mounting the electronics.

The second is the "Carbonara Cross-Hatch," which is basically a twill weave. 16 The weft strand "floats" over two or more warp strands, creating a diagonal rib. It's not as dense, but it's better at resisting twisting and has built-in channels perfect for routing wires later.

Building the Grid for the Keys

The keyboard needs a stable grid to hold all the key switches. You create this by carefully spacing the warp and weft strands. 14 The warp spacing sets the horizontal size of the key cells, and the weft spacing sets the vertical size.

If your grid is wonky, your keys will bind or feel inconsistent. The woven grid is an active part of the keyboard, affecting how it feels and sounds.

Drying and Not Warping

The final step is drying the woven chassis to make it rigid. As the pasta loses moisture and shrinks, it can create a lot of stress. 10 If you don't control this, your keyboard will warp, crack, or just fall apart.

To prevent this, you have to dry the chassis while it's still stretched on a weaving frame or jig. This tension makes the strands pull against each other evenly as they shrink. You also need a slow, even drying process - low heat, low humidity - to stop cracks from forming.

Making It All Work: Pasta-Friendly Electronics

Salty Spaghetti Wires

How do you make pasta conduct electricity? Ions! A normal salt solution conducts electricity because of free-floating positive and negative ions. 17 We can apply this to our cooked spaghetti.

After cooking the spaghetti to al dente , we soak it in a supersaturated solution of potassium chloride (KCl). We use KCl instead of regular table salt (NaCl) because potassium ions move better, making it more conductive. 19 The pasta soaks up the salty water, trapping the ions. Each spaghetti strand becomes its own self-contained, bio-organic wire.

Conductive Marinara Sauce

Another option is to create conductive traces on the surface. For this, we invented "metallic-flake marinara." It's a thick paste with a non-conductive binder (tomato paste) "doped" with a conductive filler.

You can use food-grade silver flakes or fine graphite powder as the filler. Mix it all up, and you get a thick, paintable goop. When you paint a line of it and let it dry, the particles touch and form a continuous electrical path, just like conductive ink on a circuit board.

The Lasagna Sheet PCB

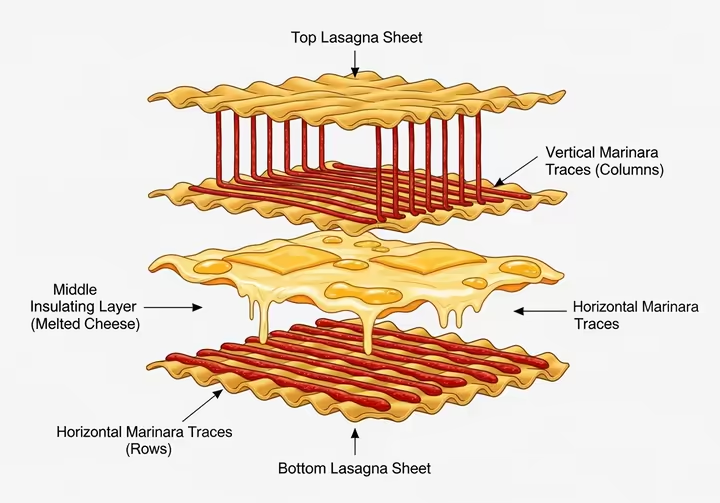

A keyboard matrix needs rows and columns of wires that cross without touching. We solve this with a multi-layered "lasagna sheet PCB" (Pasta Circuit Board). It’s inspired by a weaving technique for making double-layered cloth. 23

You take flat lasagna sheets, cooked firm. On one set, you paint the row circuits with conductive marinara. On another set, you paint the column circuits. Then you stack them with an insulating layer in between, press them, and let them dry into a solid board.

Cheese and Oil as Insulators

Preventing short circuits is a big deal, especially in a moist environment. Luckily, some foods are great insulators. Low-moisture mozzarella, when melted and re-solidified, forms a dense, non-porous solid that doesn't conduct electricity well. 24 It's the perfect bio-organic solder mask. We melt it over our marinara traces, leaving only the contact points exposed. 25

To protect the whole thing from air humidity, we use a thin coating of extra virgin olive oil. Olive oil is hydrophobic (it repels water) and a poor electrical conductor. 28 This is critical because the whole system depends on a delicate water balance, needing moisture for conductors but dryness for insulators. 19

The Pasta Key Switch

How It's Built

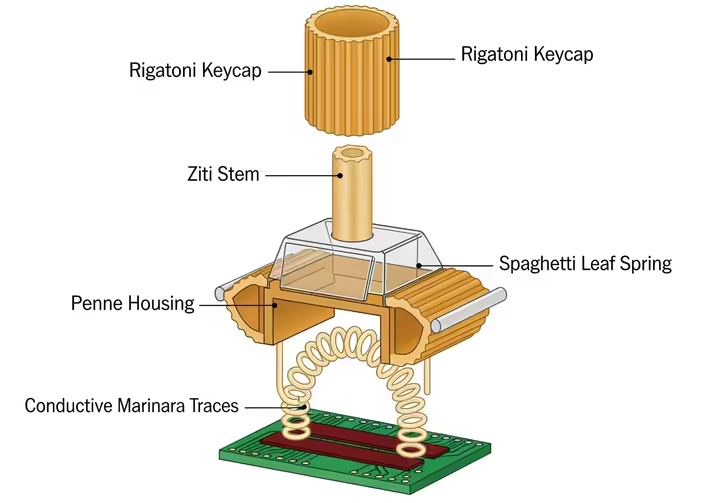

Building a key switch entirely from pasta is... a challenge. But we did it. The design copies a normal mechanical switch, which has a keycap, stem, housing, and spring. 30

Our keycap is a piece of rigatoni (wide and ridged). The stem is a shorter tube like ziti. The housing is a section of penne rigate, sized to fit the ziti stem snugly. The real trick is the spring, we use a single, semi-rigid spaghetti strand, cooked al dente , looped under the stem to act as a leaf spring.

How It Works (and Feels)

When you press the rigatoni keycap, the ziti stem pushes down on the spaghetti loop, causing it to flex. 30 That spaghetti loop is positioned right above two parallel marinara traces on the lasagna PCB. When it flexes enough, it touches both traces at once, completing the circuit.

This gives the switch a nice tactile "bump." The force needed to press the key isn't linear, it increases as the spaghetti flexes. 32 We call the moment of electrical contact the "Al Dente Actuation Point." You can tune the feel of the switch by changing the cook on the spaghetti or its position.

Raw vs. Cooked Switches

We did consider using an uncooked spaghetti strand as the actuator. Instead of flexing, the keypress would just... snap it. 5 This would provide a very sharp, single-use "clicky" feedback. But it's a destructive switch, so not very practical.

The cooked switch is the way to go. Cooking the spaghetti turns it into a viscoelastic material that can bend thousands of times. 8 This gives you a reusable, "tactile" switch. Durability makes the cooked switch the only real option for a keyboard you want to use more than once.

When Your Keys Get Tired

Even a cooked spaghetti actuator will wear out. We call it "Pre-Travel Pasta Fatigue." Every keypress causes a little bit of microscopic damage to the pasta's internal structure. 12

After thousands of presses, the spaghetti gets softer and less springy. The key will feel mushy, and eventually, it won't pop back up. The constant weight of the keycap also causes the actuator to slowly deform (that's creep). 11 So, pasta switches have to be seen as consumable parts that need regular replacement.

PastOS: Firmware for a Living Keyboard

Scanning a Mushy Grid

Normal keyboard firmware scans a grid of wires, looking for a simple on/off signal when a key is pressed. 33 But our woven pasta grid is electrically unstable. The resistance of each spaghetti "wire" changes, and the moist strands can cause electrical crosstalk.

A standard scanner would get confused by all the noise. So, we need a smarter protocol that measures the analog signal strength at each key. It figures out a baseline noise level for the grid and then looks for a big, sudden drop in resistance that signals a real keypress.

Debouncing a Noisy Switch

When a mechanical switch closes, the contacts can physically bounce, creating a burst of noisy signals. Firmware uses a "debouncing" algorithm to ignore this, usually by waiting a few milliseconds for the signal to stabilize. 33 But our pasta switches are way, way noisier.

The signal fluctuates due to vibrations, humidity, and temperature changes. A simple time-based debounce would be useless. The solution is an adaptive algorithm that can recognize the signal profile of an intentional keypress, filtering it out from all the random background noise.

The Pasta-Native Operating System (PastOS)

This hardware is so weird it needs its own software. Standard firmware like QMK assumes the hardware is stable. 34 The pasta keyboard is an active, living system. So we propose PastOS, a "Pasta-Native Operating System."

PastOS both processes input and acts as a life-support system for the keyboard. It doesn't just command the hardware, it works with it, constantly monitoring its state and adjusting itself to keep things running. It's less like a master-slave relationship and more like a biological autonomic nervous system.

PastOS Features: Humidity and Stale Noodles

A core feature is "Automatic Humidity Compensation." The keyboard's electrical properties change with ambient humidity. 8 PastOS would use a sensor to check the humidity and dynamically adjust the sensitivity of the key scanner. This makes the keys feel the same whether it's a dry or a humid day.

Another key feature is the "Stale Noodle" protocol. During idle time, the OS would check the resistance of every single wire in the matrix. If a spaghetti strand's resistance is too high, it means it has dried out ("gone stale"). PastOS flags the keys on that wire as broken to prevent errors.

Care and Feeding of Your Pasta Keyboard

Keeping Bugs Away

Your number one enemy is pantry pests, like grain weevils and flour beetles. 35 If they infest your keyboard, they will eat it from the inside out, causing total structural failure. Once they're in, they're almost impossible to get out.

Prevention is key. Store the keyboard in a hermetically sealed container, like a bell jar. Inspect it weekly with a magnifying glass for any signs of pests. If you catch an infestation early, you can try putting the whole keyboard in a freezer at 0°F (-18°C) for four days. 36

Water is Life... and Death

Managing moisture is the hardest part of maintenance. You need some moisture for the circuits to work, but too much will lead to mold. 37 It's a delicate balance. Use desiccant packets (silica gel) in the storage container to control humidity. 37

Wiping the surface with a bit of white vinegar every couple of weeks can also inhibit mold. 38 To counteract the circuits drying out, you'll need to perform a "Sauce Rehydration Protocol." This means carefully misting the marinara traces and spaghetti wires with sterile water to restore their conductivity.

Common Problems: Sticky Keys and Chassis Sag

Over time, you'll run into mechanical problems. "Key-switch stiction" happens when the conductive marinara sauce dries out and gets gummy, making keys stick. Regular cleaning and rehydration can prevent this.

"Chassis Sag" is the slow, inevitable drooping of the keyboard under its own weight. This is due to material creep. 11 After a few months, the whole thing will start to bow in the middle. You can fight this by periodically re-tensioning the chassis on its frame.

Repairs and Replacements

Since the key switches are consumable, you'll need to replace them. It's not easy. You have to delicately un-weave the area around the broken key without breaking anything else.

Then you put the new part in and meticulously re-weave the section, matching the original pattern and tension. 14 If you mess it up, you create a weak spot that will just fail again. This keyboard comes with a high maintenance burden.

The Inevitable Modding Community

The Great Sauce Debate

Any new tech inspires debate, and this will be no different. The first big fight will be the "Great Sauce Debate." "Sauce Purists" will stick to the original design, using brine-infused spaghetti for wires and marinara for traces. 17

The "Pesto Technicians" will argue for a more robust design. They build the chassis from untreated spaghetti, paint all the circuits on, and use basil pesto as an insulator. Pesto is lipid-based and hydrophobic, making it much more water-resistant than mozzarella. 28

The Artisanal Keycap Scene

Just like in the regular keyboard world, a scene for custom pasta keycaps will pop up. 39 People will move beyond rigatoni to explore other shapes.

Expect heated arguments about the "finger-cradling concavity" of an orecchiette versus the "bi-stable feel" of a farfalle. Some might even use radiatore, claiming the fins help with heat dissipation during intense gaming. All of this will be discussed with extreme, technical-sounding seriousness. 32

The Search for the Perfect Sound

The true nerds will obsess over acoustics. One group will chase the ultimate "brittle snap." They'll use uncooked pasta to get a high-frequency, sharp, clean sound.

The other group will pursue the perfect "soggy thud." These builders prefer a fully hydrated, heavily sauced keyboard. The moisture dampens the sound, creating a low-frequency, resonant "thud" that they will tune by experimenting with sauce viscosity.

The "Fresh vs. Dried" War

The deepest debate will be "Fresh vs. Dried." The "Dries" are pragmatists. They argue that dried pasta is the only logical choice for a stable, long-lasting device.

The "Freshies" are the artisans. They insist on using fresh pasta dough, claiming its plasticity allows for more complex weaves and provides a superior feel and sound. 3 They accept the insane maintenance burden as the price for a truly bespoke creation.

Works cited

- Characterization of Semolina and Pasta Obtained from Hard ..., https://pmc.ncbi.nlm.nih.gov/articles/PMC12154536/

- Incorporating Fresh Durum Wheat Semolina Pasta Fortified with Cardoncello (Pleurotus eryngii) Mushroom Powder as a Mediterranean Diet Staple - MDPI, https://www.mdpi.com/2076-3921/14/3/284

- Pasta Made Easy: The Science Behind the Dough, https://scifood.blog/2025/01/03/pasta-made-easy-the-science-behind-the-dough/

- The 5 Best Pasta Brands of 2025 (We Tried 8) - The Kitchn, https://www.thekitchn.com/the-everyday-pasta-brand-italians-buy-and-you-should-too-257659

- www.scribd.com, https://www.scribd.com/document/699930766/Tension-Lab#:~:text=based%20on%20measurements.-,Testing%20found%20that%20the%20maximum%20tensile%20force%20and%20ultimate%20tensile,be%20used%20for%20educational%20purposes.

- Effect of Pasta Cooking Time on the Content and Fractional Composition of Dietary Fiber, https://www.researchgate.net/publication/263185585_Effect_of_Pasta_Cooking_Time_on_the_Content_and_Fractional_Composition_of_Dietary_Fiber

- New insights into how the structure of starch synergistically affects ..., https://academic.oup.com/ijfst/article/60/1/vvae031/8052669

- The Effect of Humidity on Pasta - AZoM, https://www.azom.com/article.aspx?ArticleID=20642

- Spaghetti/Noodle Tensile Rig | Stable Micro Systems, https://www.stablemicrosystems.com/texture-analysis/attachments/spaghettinoodle-tensile-rig/

- Pasta Drying and the Effects of Humidity and Temperature - Calright Instruments, https://calright.com/application/pasta-drying-effects-humidity-temperature/

- industrialphysics.com, https://industrialphysics.com/knowledgebase/articles/creep-failure-vs-fatigue-in-metals/#:~:text=Creep%20results%20in%20deformation%2C%20while,an%20eventual%20split%20or%20rupture.

- Creep Failure vs. Fatigue in Metals: Differences and Testing Methods, https://industrialphysics.com/knowledgebase/articles/creep-failure-vs-fatigue-in-metals/

- What is the difference between creep fracture and fatigue fracture? | The Armoloy Corporation, https://armoloy.com/faq/what-is-the-difference-between-creep-fracture-and-fatigue-fracture/

- Four basic basketweaving techniques are represented in this gallery ..., https://hfma.willamette.edu/pdf/virtual-tours/grand-ronde-vt/basketweaving.pdf

- Basketry and mathematics | EBSCO Research Starters, https://www.ebsco.com/research-starters/science/basketry-and-mathematics

- Textile - Weaves, Fabrics, Patterns | Britannica, https://www.britannica.com/topic/textile/Basic-weaves

- Why Measure Conductivity Or Salinity? - Montclair State University, https://www.montclair.edu/water-science/environmental-services/conductivity-salinity/

- 18.3 Electrolytes, ionisation and conductivity | Reactions in aqueous ..., https://www.siyavula.com/read/za/physical-sciences/grade-10/reactions-in-aqueous-solution/18-reactions-in-aqueous-solution-03

- Conductivity of Aqueous Salt Solutions; Mechanism and Applications in Medicine/Engineering - ResearchGate, https://www.researchgate.net/profile/Richard-Sauerheber-2/publication/341193917_Conductivity_of_Aqueous_Salt_Solutions_Mechanism_and_Applications_in_MedicineEngineering/links/5eb329df92851cbf7fad9e83/Conductivity-of-Aqueous-Salt-Solutions-Mechanism-and-Applications-in-Medicine-Engineering.pdf

- (PDF) Conductivity of Aqueous Salt Solutions; Mechanism and Applications in Medicine/Engineering - ResearchGate, https://www.researchgate.net/publication/341193917_Conductivity_of_Aqueous_Salt_Solutions_Mechanism_and_Applications_in_MedicineEngineering

- Conductive Polymers - Engineering LibreTexts, https://eng.libretexts.org/Bookshelves/Materials_Science/Supplemental_Modules_(Materials_Science)/Materials_and_Devices/Conductive_Polymers

- Electrical and Electrochemical Properties of Conducting Polymers - PMC, https://pmc.ncbi.nlm.nih.gov/articles/PMC6432010/

- Weaves of Woven Fabrics Weave is the interlacment of warp and weft yarns to produce a woven fabric. Fabrics are manufactured in, https://www.eoimadrid.gov.in/pdf/Weaves%20of%20Woven%20Fabrics%20MJ%20(1).pdf

- Dielectric properties of process cheese from 0.3 to 3GHz | Request ..., https://www.researchgate.net/publication/223085287_Dielectric_properties_of_process_cheese_from_03_to_3GHz

- The relationships between the chemical, dielectric and sensory properties of Edam cheese during ripening, https://cjfs.agriculturejournals.cz/pdfs/cjf/2001/03/02.pdf

- Measurements of the Dielectric Properties of Cheddar Cheese - Taylor & Francis Online, https://www.tandfonline.com/doi/abs/10.1080/08327823.1997.11688319

- Dielectric properties of foods relevant to RF and microwave pasteurization and sterilization - Washington State University, https://wpcdn.web.wsu.edu/wp-labs/uploads/sites/1254/2016/05/tang69.pdf

- (PDF) Investigation of the Efficiency of Olive Oil as Dielectric Material and Its Economic Value on the Environment Using Its Dielectric Properties. - ResearchGate, https://www.researchgate.net/publication/301567465_Investigation_of_the_Efficiency_of_Olive_Oil_as_Dielectric_Material_and_Its_Economic_Value_on_the_Environment_Using_Its_Dielectric_Properties

- Study of the electric resistivity of Vegetable oil: Argan, Avocado and ..., https://www.scholarsresearchlibrary.com/articles/study-of-the-electric-resistivity-of-vegetable-oil-argan-avocado-and-olive.pdf

- The Ultimate Guide On Mechanical Keyboard Switches: All You ..., https://varmilo.com/blogs/switches/the-ultimate-guide-on-mechanical-keyboard-switches-all-you-need-to-know

- Keyboard Switches - How Computer Keyboards Work | HowStuffWorks, https://computer.howstuffworks.com/keyboard3.htm

- Mechanical Keyboard Guide - Das Keyboard Mechanical Keyboard ..., https://www.daskeyboard.com/blog/mechanical-keyboard-guide/

- Keyboard Matrix Scanning and Debouncing – Frog in the Well, https://summivox.wordpress.com/2016/06/03/keyboard-matrix-scanning-and-debouncing/

- Debouncing - ZMK Firmware, https://zmk.dev/docs/features/debouncing

- I Found Bugs in My Cereal, Pasta or Cake Mix. What Do I Do ..., https://extension.rutgers.edu/food-safety/bugs-in-my-cereal

- Stored Product Pest or Pantry Pest Management - Dodson Pest Control, https://www.dodsonbros.com/stored-product-pest-pantry-pest-management/

- Preventing Mold Spoilage in Food Packaging - Multisorb, https://www.multisorb.com/blog/desiccants-food-packaging-prevent-spoilage/

- Clean Label Mold Inhibitors for Baking - Oklahoma State University Extension, https://extension.okstate.edu/fact-sheets/clean-label-mold-inhibitors-for-baking.html

- Keyboard Glossary — Keyboard University, https://www.keyboard.university/resources/glossary-h447f